Like the Lencos I am most known for improving, the Schoolhouse needed some work, as some of the original hand-hewn beams on which the floors rested had rotted, along with large patches of floor. So, we cut off the rotten sections, replaced them with modern joists, and used some sections of the original floors in a pattern with the 2”-thick hemlock chosen for the floorboards. I decided to paint the walls a cheerful pastel yellow to increase the light from the many large windows, as the woodworking must be done to high levels of accuracy, and there is no beating natural light. As a testimony to both history and nature, I have left the ceiling as-is, with sections peeling (scraped regularly), for that fractal look of natural patina and weathering.

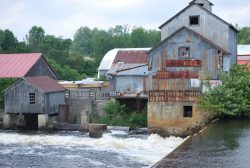

I have various suppliers of lumber, and again, as with my own work, prefer historical companies, smaller companies, dealing with people employed by these smaller companies. Here are photos of one of my favourite lumber mills, the Chisolm Mill, a historic wood mill established on the river, when water was the driving force behind mills, in 1857, a few hours drive away on the same beautiful highway my own Schoolhouse is found, and so always a treat to go visit them. They are suppliers of many of my most beautiful woods.

Keeping things on a somewhat personal footing as much as I can, as always to find the best way to where I want to go sonically and mechanically, I rely on the help of my machinist in designing my various Lenco pieces, who I consult and to whom I give some free rein in my designs, as he knows metals, methods of fastening, and other metal machining esoterica, and we discuss the best ways to get where I want, and so keep things practical and effective. These days everyone is fixated on CNC machinery and manufacturers use them as a form of advertising, but let’s not forget the astonishing levels of accuracy (and performance) reached by record player manufacturer/legends Garrard, Thorens, EMT, of course Lenco and others using the traditional lathe. As well as lathes, my machinist’s shop also includes a couple of CNC machines, to be used where they are best suited. He is from Liechtenstein, trained in Switzerland, coincidentally the country of origin of the Lencos, and has fallen in love with the space in Canada and lives out in the smaller villages out in the wilderness along the upper reaches of the Ottawa River, home as well to moose, wolves, bears, deer and the mighty woodpecker. He works in a well-equipped if small shop (like mine): many times I have driven out in the dead of night far along unlit country roads in -20C, to pick up newly-machined prototypes and finished pieces (summer drives are less exciting but more pleasurable :-)). He has been excellent to work with, and I will stand by him, which means I must have my parts made in small limited runs, but I prefer this business model, which suits the limited number of record players I can build a year anyway.

I resort to a professional outfit for my painting, which includes either a very tough polyurethane coating for my stock Lenco pieces, or powder-coating for my new chassis and platters.